Signal converters are essential components in various electronic devices and systems, as they are responsible for converting one type of signal into another. This conversion process is crucial for ensuring compatibility between different devices and enabling seamless communication between them. In recent years, there have been significant advancements in signal converter manufacturing processes, leading to the development of more efficient, reliable, and versatile converters. In this article, we will explore some of the latest manufacturing processes used in signal converter production and their impact on the industry.

Another important development in signal converter manufacturing is the integration of digital signal processing (DSP) technology into converter designs. DSP technology allows for more precise signal processing and control, leading to improved signal quality and faster response times. By incorporating DSP technology into signal converters, manufacturers can offer more advanced features and functionalities, such as signal filtering, amplification, and modulation, in a compact and cost-effective package.

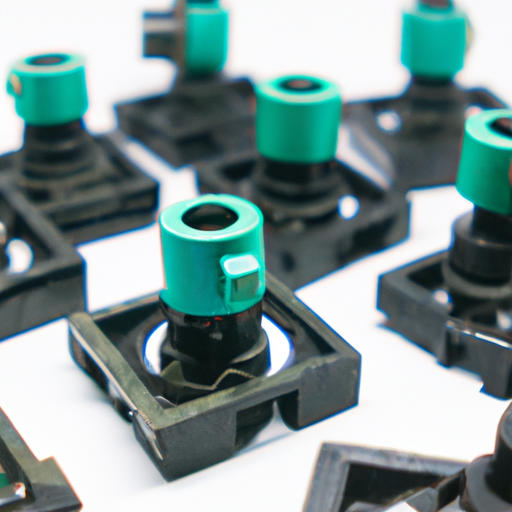

Furthermore, the trend towards miniaturization and integration in signal converter manufacturing has led to the development of smaller and more compact converters with higher performance capabilities. Manufacturers are now able to pack more functionality into smaller form factors, making signal converters suitable for a wider range of applications, including portable devices, wearable electronics, and IoT (Internet of Things) devices. This trend towards miniaturization has been made possible by advancements in semiconductor technology, allowing for the integration of multiple functions onto a single chip.

In addition to advancements in materials, technologies, and miniaturization, manufacturers are also focusing on improving the efficiency and sustainability of signal converter manufacturing processes. For example, many companies are implementing lean manufacturing principles and energy-efficient production techniques to reduce waste, minimize environmental impact, and lower production costs. By optimizing production processes and reducing energy consumption, manufacturers can improve their competitiveness in the market while also contributing to a more sustainable future.

Overall, the latest signal converter manufacturing processes are characterized by a focus on performance, reliability, miniaturization, integration, efficiency, and sustainability. By leveraging advanced materials, technologies, and manufacturing techniques, manufacturers are able to produce high-quality converters that meet the demands of modern electronic devices and systems. As the demand for signal converters continues to grow in industries such as telecommunications, automotive, industrial automation, and consumer electronics, manufacturers will continue to innovate and improve their production processes to stay ahead of the competition and meet the evolving needs of customers.